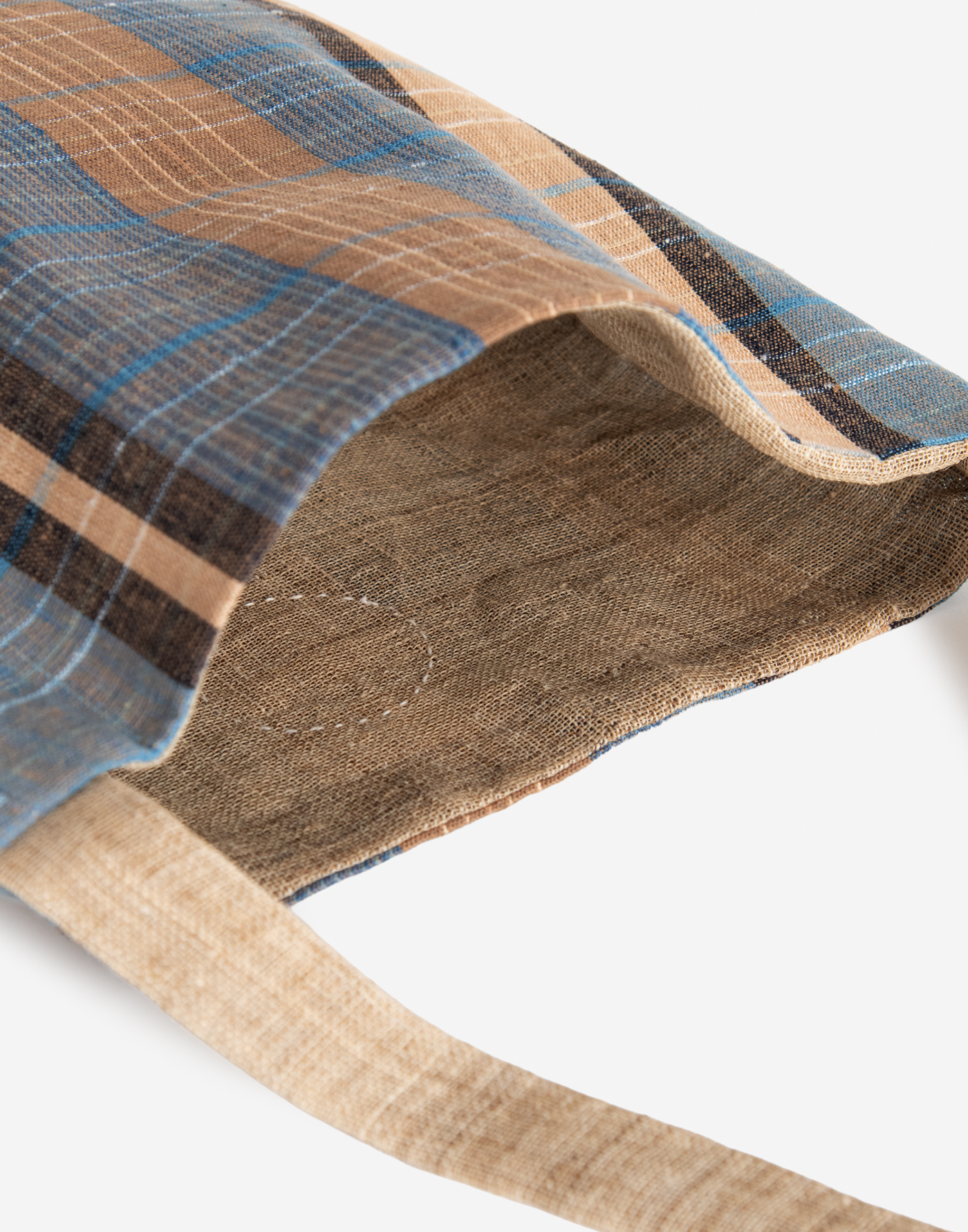

Tamba Cloth and Hemp Cloth Handbag

| Tamba Cloth and vintage Hemp Cloth Handbag. Tamba Cloth Tamba cloth is a plain-woven, handwoven fabric produced in Saji Village, Tamba Province. It is made by interweaving hand-spun cotton and tsumami silk spun from waste fibers. It is woven in a grid pattern using hand-spun yarn dyed with plant-based dyes. The dyes are derived from plants available around the village. Using indigo and tea as the base, they employ materials such as the bark of wild chestnut trees, Japanese bayberry bark, alder bark, and the roots of plants like knotweed, Jerusalem artichoke, and loquat that grow along field paths. This fabric was woven extensively from the late Edo period to the early Meiji era and was cherished in the Kyoto area, where it was made into futons and kosode kimono. It declined and was forgotten by the Taisho era. In the early Showa period, Muneyoshi Yanagi discovered this charming striped cotton by chance at a Kyoto morning market and asked craft researcher Rokuro Uemura to identify its place of origin. In 1931 (Showa 6), Kamimura identified the striped cotton as Saji cotton, woven in Saji Village. In 1953 (Showa 28), under Kamimura's guidance, Tamba cloth was recreated. In 1954 (Showa 29), with the backing of Kamimura and Yanagi, the local preservation society established the Tamba Cloth Heritage Center. Primitive Cloth Since ancient times, the Japanese have gathered fibers from wild plants growing in mountains and fields, cultivated plants, spun the fibers into thread, and wove cloth to make their own clothing. The main plants used were kozo (paper mulberry), Irakusa (hemp), ohyo (paper mulberry), su (paper mulberry), hemp, gaku-ma (hemp), nettle, and akkan (hemp). This practice can be traced back to the Jomon period. _Archaeological sites from the Jomon period have yielded hemp thread, woven abaca cloth, and pottery with traces of fabric. From the Jomon period until the early Showa era, cloth made from plant fibers was produced. Commoners spent considerable effort and time crafting it during farming breaks. From trees, the fibrous layer beneath the bark was extracted, then boiled for long periods in ash water or fermented to isolate the fibers. From grasses, after cutting, the fibers were extracted by boiling to rot the outer skin or scraping it off with blades. The extracted fibers were then split into fine strands one by one, twisted or knotted together to form thread. This process of making thread is called thread spinning (ito-umi). The spun thread was wound onto spindles, wound onto spindles, and then woven on looms to become cloth. Cotton 96%, Silk 4% Handle, lining: Hemp 100% Size: Free Width 35 / Height 35 / Handle 59 *cm |

|||||

|